WE6

WE6

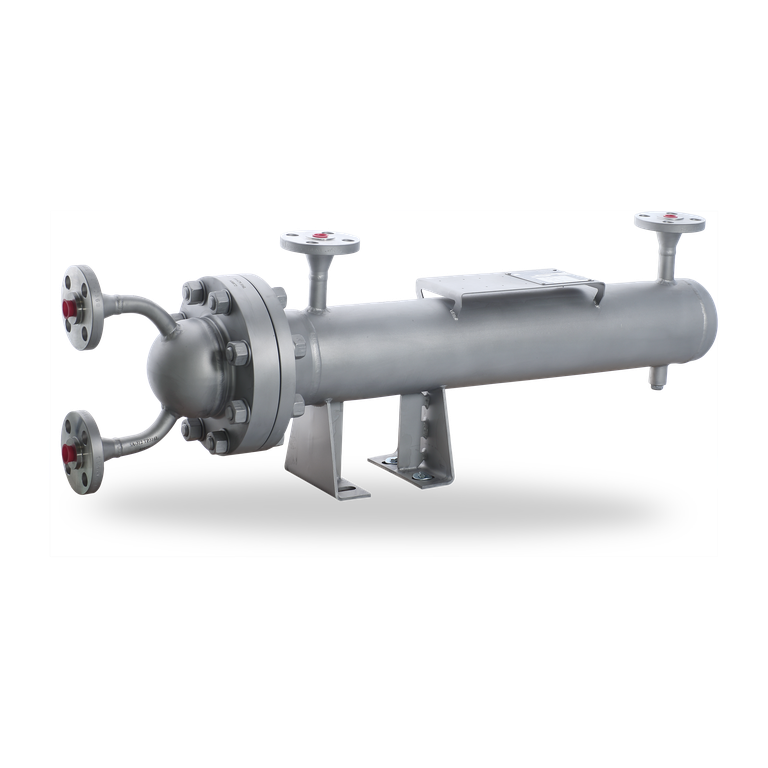

| Item | Description |

| A | Cooling circuit vent |

| B | Barrier medium IN |

| C | Barrier medium OUT |

| D | Cooling water IN |

| E | Cooling water OUT |

| F | Cooling circuit drain |

WE6

Features

Heat exchangers of the WE6 range are used to cool process/barrier fluids in seal supply circuits. WE heat exchangers are available in two standard sizes and are API 682 conform. The process/barrier medium is directed through the tube and the cooling medium through the shell.

For simple draining or venting of the cooling water side, the heat exchanger can also be supplied with ventilation/drainage ball valves. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682).

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

For simple draining or venting of the cooling water side, the heat exchanger can also be supplied with ventilation/drainage ball valves. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682).

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

Advantages

- Operating limits up to 45 bar / 260 °C (tube side): suitable for a wide range of demanding operating conditions.

- Heat exchanger can be dismantled: for optimum and simple cleaning of the tubes

- Cooling water side and process side can be completely vented and drained

- 1.4404 stainless steel: high resistance to corrosive fluids

Standards and approvals

- PED 2014/68/EU (Design and production in accordance with EU Pressure EquipmentDirective)

- ASME VIII, Div. 1 (Design, calculation and production)

Recommended applications

- Chemical industry

- Petrochemical industry

- Oil and gas industry

- Refining technology

Notes

Cleaning:

Cooling water side: the area around the tubes can be cleaned mechanically after the housing is removed.

Process/barrier medium side: flush with a suitable solvent.

Cooling water side: the area around the tubes can be cleaned mechanically after the housing is removed.

Process/barrier medium side: flush with a suitable solvent.

Product variants

| Designation | WE6055/A008-D0 | WE6055/A009-D0 | WE6055/A010-D0 | |||

|---|---|---|---|---|---|---|

| Tube | Shell | Tube | Shell | Tube | Shell | |

| Design code | ASME VIII, Div. 1 | ASME VIII, Div. 1 | ASME VIII, Div. 1 | |||

| Process connections | Flange 3/4", 600 lbs |

3/4" NPT (f) | Flange 3/4", 600 lbs |

Flange 3/4", 150 lbs (threaded) |

Flange 3/4", 600 lbs |

Flange 3/4", 150 lbs (welded) |

| Allowable pressure1) | 55 bar (798 PSI) |

15 bar (217 PSI) |

55 bar (798 PSI) |

15 bar (217 PSI) |

55 bar (798 PSI) |

15 bar (217 PSI) |

| Allowable temperature1) | -29 ... +260 °C (-20 ... +500 °F) |

-29 ... +260 °C (-20 ... +500 °F) |

-29 ... +260 °C (-20 ... +500 °F) |

-29 ... +260 °C (-20 ... +500 °F) |

-29 ... +260 °C (-20 ... +500 °F) |

-29 ... +260 °C (-20 ... +500 °F) |

| Cooling capacity (kW)2) | 6.0 | 6.0 | 6.0 | |||

| Metal parts | 316/316L | 316/316L | 316/316L | |||

| O-Rings | Viton® | Viton® | Viton® | |||

| Screws | Stainless steel SA-193 B8M2 |

Stainless steel SA-193 B8M2 |

Stainless steel SA-193 B8M2 |

|||

1) Other operation condition on request.

2) The cooling performance depends on the available fluids, their temperatures and flow rates. Please contact EagleBurgmann for professionally selecting the correct heat exchanger.

Similar products

WDK

WDK5120 heat exchangers are used to cool process/barrier fluids in seal supply circuits. The heat exchanger has a wound double helix around the guide tube. Process/barrier medium in the tubes, cooling medium around the tubes.

Circulation based on API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

Circulation based on API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

WED

Heat exchangers of the WED range are used to cool process/barrier fluids in seal supply circuits. Designed as a tubular heat exchanger with integrated guide plates, the process/barrier medium is directed through the shell of the WED and the cooling medium through the tubes.

Circulation based on API 682 / ISO 21 049: Plan 21, Plan 22, Plan 23, Plan 41

Circulation based on API 682 / ISO 21 049: Plan 21, Plan 22, Plan 23, Plan 41

WED5

Heat exchangers of the WED5 range (photo: WED5050/A020-D1) are used to cool process/barrier fluids in seal supply circuits. WED5 heat exchangers are available in 3 standard sizes and are API 682 conform. The process/barrier medium is directed through the tube and the cooling medium through the shell. For simple draining of the cooling water side, the heat exchanger can also be supplied with drainage ball valves. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to mechanical seal (optional in accordance with API 682).

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41